NOV Mono is a global manufacturer of progressing cavity pumps and pump parts.

NOV is a leading provider of oilfield products and services to the oil and gas industry, with more than 140 years’ experience.

Mono first began manufacturing progressing cavity pumps in 1935 and our heritage is built on this world-renowned design.

Conjointly they now produce a wide product range suitable for the pumping of fluids within the waste water, chemical, food, beverage, paper, mining, mineral processing, marine, agricultural and oil and gas sectors.

Product Range

- Pressure Sewer Systems

- EZstrip™ Family

- PC Pumps

- Rotary Lobe Pumps

- Solar Products

- Artificial Lift

- Grinders

- Screens

- Packaged Systems

- ODD Pumps

- Centrifugal Pumps

Featured Pumps

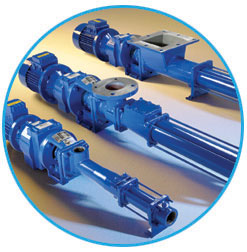

Compact C Range

The Compact C Range of progressing cavity pumps has been manufactured by Mono to offer you a pump designed to fit into compact spaces, whilst reliably performing to the maximum duty requirements of your application.

The Compact C Range of progressing cavity pumps has been manufactured by Mono to offer you a pump designed to fit into compact spaces, whilst reliably performing to the maximum duty requirements of your application.

Features include good suction lift capability of over 8 meters, positive displacement for process control and variable speed for accurate dosing.

Borehole Pump

The Mono borehole pump is the essence of simplicity in design.

The Mono borehole pump is the essence of simplicity in design.

The simple positive displacement, Mono designed rotor and stator are immersed below draw-down level in the bore or well.

Mono Borehole pumps have provided reliable water supply to thousands of farmers, towns and villages around the world.

EZstrip™ Transfer Pump

The EZstrip is the latest revolutionary new pump design which can be ‘Maintained-in-Place’ (MIP), making a day-long maintenance operation become a 30 minute job.

The EZstrip is the latest revolutionary new pump design which can be ‘Maintained-in-Place’ (MIP), making a day-long maintenance operation become a 30 minute job.

This innovative pump is the biggest leap forward in progressing cavity (PC) pump design for 30 years and is an extension of Mono’s popular Compact C Range.

The EZstrip has been specifically designed to provide a quick and easy way to disassemble, de-rag and maintain a PC pump in-situ, eliminating the costly maintenance and down time that servicing can often cause.